Test Illumination StripsRapid HIV testing for infants in Africa

HIV/AIDS is a major public health concern in many parts of Africa. Although HIV testing of infants at health facilities in recommended by the World Health Organization to enable them to start treatment as soon as possible, HIV testing is unavailable in many rural, inaccessible areas and many HIV-positive children in developing countries remain undiagnosed.

A center housed within the McCormick School of Engineering at Northwestern has developed a process to rapidly test infants for HIV. Northwestern student Anna Petersen described the potential of the new technology developed by the center.

Problem

"The center's technology has the capacity to revolutionize medical care in countries like Mozambique and Zambia," Petersen said. With this new technology, "it will be possible for infants to be tested and diagnosed on site in less than an hour, which will be a big improvement over current methods that require several days to obtain the patient's results after the test has been administered."

However, the test strips are read visually by clinicians and approximately one third of positive cases are missed and read instead as negative due to the test's low sensitivity. To read the strips, the testers first confirm the presence of a control line to ensure the test was administered and processed correctly. Once the line has been verified, the tester looks for the presence of the second test line. Any presence of a test line indicates positive test for HIV. Often the test lines appear faint, which pose a challenge for testers to determine an accurate diagnosis.

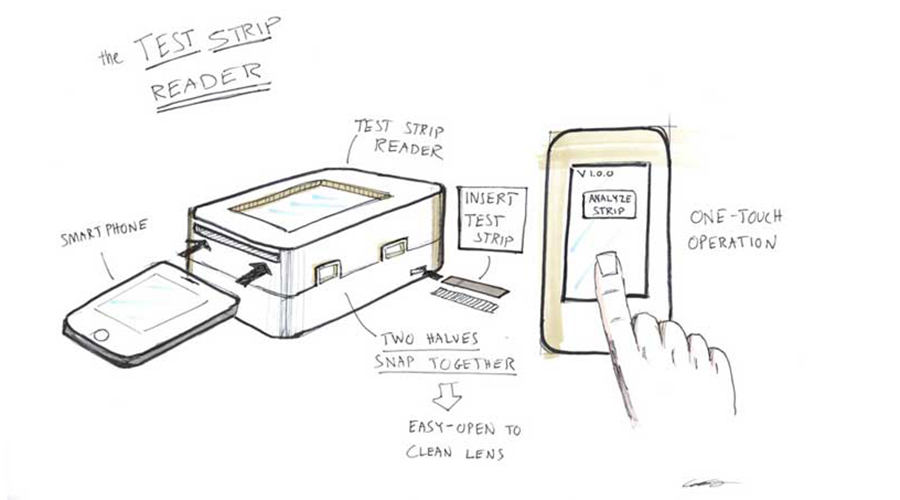

That's where this interdisciplinary team of undergraduates enrolled in DSGN 384, a course offered by the Segal Design Institute at Northwestern, enters the picture. Petersen is a part of this team along with fellow students Christina Lundgren and Charlie Tokowitz. Together, they are working with the center to identify what exactly in the testing process contributes to the test's low sensitivity and the number of false negatives. Next, they hope to develop an algorithm that will analyze the test strips and determine a diagnosis. An accurate, working algorithm would be able to provide the foundation for a better stand-alone test strip reader, the team stated.

"In theory, [a stand-alone reader] would remove any human error and subjectivity from the reading of the strip," explained Petersen.

The Process

One of the team's instructors, Dan Brown, said that the team has made extensive efforts to frame the problem by conducting research into the how the test strip is manufactured and how it is administered in the field, as well as finding out what diagnostic technology currently exists on the market.

"I have found this project interesting in that it challenged the students to dive deeply into the problem-finding and stakeholder need-finding aspect of the design process in order to correctly frame the problem," Brown said. "This qualitative upfront research and benchmarking of the existing situation is often an overlooked component of the process. With highly technical challenges such as the test strip problem, there is a tendency to focus on the quantitative technology requirements independently of the qualitative stakeholder's behaviors, expectations, and interactions. When teams skip the front-end design research process and rush quickly into a solution-focused approach, they often will miss the opportunitiy to get to the root of the technical problem as well as address the other human-centered conditions necessary for creating a valid and viable solution."

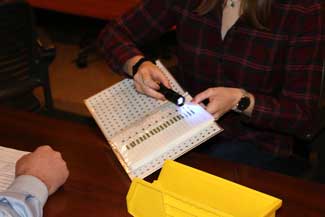

To research the method of reading the tests, the team designed a testing process where 37 participants diagnosed a set of 20 different test strips.

The Solution

"We were able to better characterize how difficult it can be to read the test by the naked eye" thanks to the user testing, said Lundgren.

Team member Anna Petersen added that the user observation revealed several factors that could influence whether the test strips are read properly.

"We were able to not only look at the quantified results of the test, but also observe the participants' behavior and reading strategies to provide insight into why so many test strips are being misread in the field. Some of our users had eye correction while some did not. Some chose to look very closely at the paper whereas others maintained about two feet of distance between their eyes and the strip."

The student team within the Manufacturing and Design Engineering Program and Segal Design Program still has a lot of work to do and team member Christina Lundren described what lies ahead.

"For the rest of this project, our team is going to continue to research and characterize the testing process. We have to identify where this process can be improved in order to be used in the field," said Lundgren. "In the future, we want to see another team pick this project back up and use the metrics we determine to build a device to read the strips."

Empathy is an integral part of the design innovation process, and this project has required that quality from this team.

"Ultimately, we aren't putting in the time and effort on this project to earn a good grade," said Petersen. "We see that this technology has the potential to improve healthcare services for children in the world's most vulnerable countries, and we want to contribute to that cause in any way we can."

ProgramsBS in Manufacturing & Design Engineering, Segal Design Certificate

Faculty AdvisersJohn Anderson, Dan Brown