OptikAn all-in-one case for biweekly contacts users

Biweekly contact lens users often find it difficult to remember to change their contacts on time. While enrolled in a course titled Human-Centered Product Design taught by Professor David Gatchell, a team of undergraduate students designed a solution to answer the question: “How might we help biweekly contacts users change their contacts accordingly?”

Problem

Biweekly contacts users often guess when it is time to change their contact lenses or risk wearing them until they are uncomfortable. While many users resort to methods such as phone reminders and post-it notes, these methods require too purposeful action from busy users to maintain. By wearing contacts for longer than two weeks, users risk corneal scratches and eye infections that come with improper and unhygienic lens care.

Solution

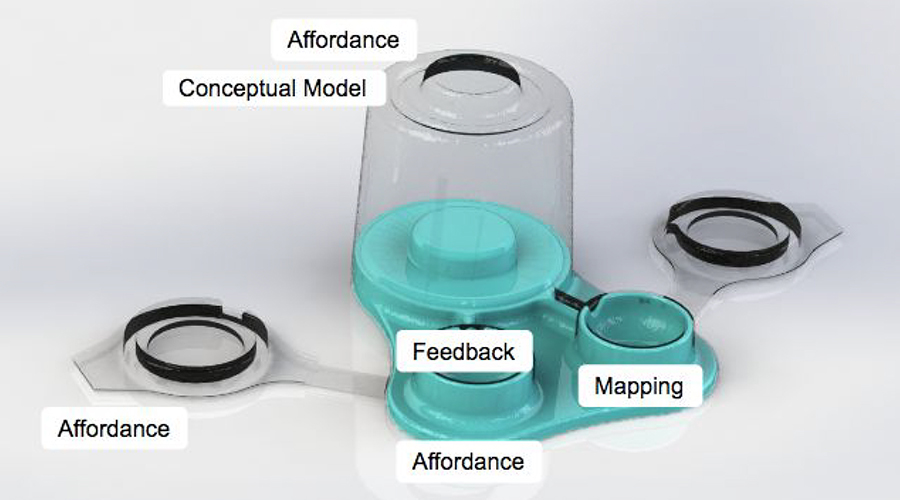

The team designed Optik, an environmentally friendly all-in-one case, as the solution to this problem. Optik consists of the packaging for a set of biweekly lenses (matched with right and left eye prescriptions) and a reservoir pre-filled with two weeks worth of contact solution. The compartments housing the lenses serve as a case.

Pressing down on the top of the reservoir fills the lens compartments through a small hole with one or two presses of the finger. As the solution in the clear reservoir visibly runs low, users know that it will be soon time to switch contacts.

The design has efficient mapping; users will always be inclined to place Optik with the case facing towards them which means the user will never be confused about which side is left or right. The slightly protruding top of the reservoir affords itself to be pushed, which pumps the solution into the case.

Optik does not require users to develop a new routine for lens care. The familiar routine of filling the case and emptying it out before filling it up again at the end of the day remains intact. To use Optik, the user only needs to adopt the habit of pressing on a pump to fill the case. During user testing, the team found that this adoption was easily done.

Development Process

The team developed Optik by moving through these stages of the design process: ideation, concept selection, user testing, and prototyping.

The team initially started with three ideas: a clip-on timer, an automatic timer for the lid, and a pillbox-style container. However, after market research, the team learned that the two timers were too similar to current solutions, so they conducted more ideation and brainstorming. They created mock-ups inspired by a pillbox, a pump, and a bird feeder.

The team 3D-printed three iterations of a mock-up inspired by a bird feeder. Next, the team modified one of the 3D-printed “bird feeder”-style iterations with a flexible top and reduced the hole sizes with hot glue. The team found that the reduced hole size was small enough to let fluid through only when moderate pressure is applied with the flexible top. Two molds for a flexible bellows-style top were 3D-printed and then used to

Team members even took turns emptying and refilling the mock-up every time they used their own contact cases. The team members found that the design could be operated with only tactile feedback (unlike existing contact solution bottles which require visual alignment with the case to add fluid). This difference represents an important advantage for visually-impaired users who (for obvious reasons) would not be wearing their contact lenses while using the device.

Next, the team moved onto creating a final design: a combination of the bird feeder and the pump. The team incorporated snap fit lids to alleviate hygiene issues; germ and salt could potentially build up between the threads of existing contact cases.

To manufacture a working prototype, the team decided to use polystyrene because vacuum forming was the primary method available for manufacturing their prototype in the Segal Prototyping and Fabrication Lab. The polystyrene sheets heated up easily and formed successfully around the molds created by the team, although folds were unavoidable with such a low-fidelity mock-up.

The team chose PET as the material for Optik to ideally be manufactured with on a mass scale. PET is recyclable, extremely resistant to both salt and fresh water, and is resistant to weak acids and alkalis. Thus, Optik made from PET would be safe to use.

Faculty AdviserDavid Gatchell

ProgramManufacturing and Design Engineering (MaDE)