DTC Student Spotlight: John Chen

Embracing the lessons of design thinking and communication, Chen (BS ’24) and Medical Makers teammates are applying principles of human-centered design to developing wearable technology capable of predicting the release of bodily waste in patients with incontinence.

Spending the entirety of his first year at Northwestern University learning remotely because of the COVID-19 pandemic, John Chen (BS ’24) found a bright spot in Design Thinking and Communication (DTC), the two-quarter course required of all first-year Northwestern Engineering students.

Not only did DTC foster interaction with peers and help Chen build a deeper sense of community at Northwestern amid online education, but the classes co-taught by Janice Mejia and Deborah Wood introduced Chen to the energizing and perspective-changing principles of human-centered design.

“It’s so easy in the creative process to overthink things, but DTC grounded me in the valuable lesson that everything needs to be realistic for the client and the user,” Chen said. “I found that empowering.”

DTC engineering instructor Janice Mejia noted Chen’s enthusiasm.

“John was someone clearly and genuinely interested in the design process, which you could see with his focus on research, his willingness to evaluate existing products and user challenges, and his high-quality work,” Mejia said.

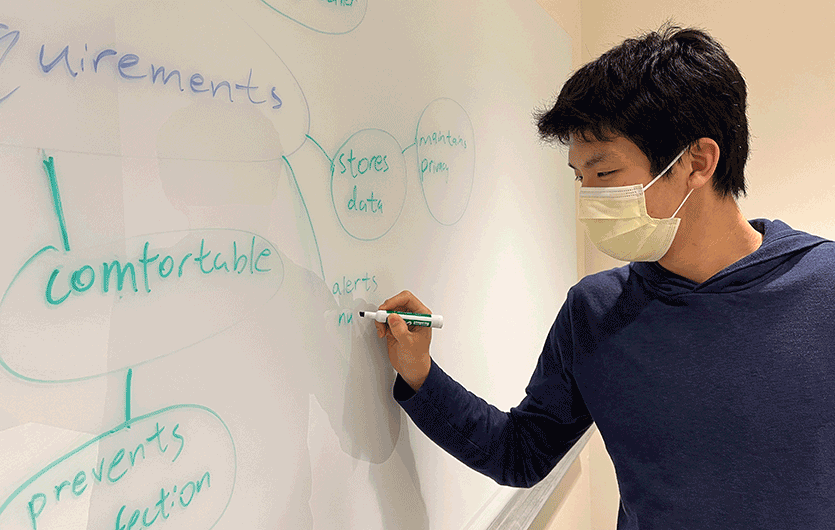

Putting DTC lessons into action

When Chen arrived on campus this past fall for his second year, he was eager to apply the design process to an area of interest and capitalize on a more conventional campus environment. A biomedical engineering major contemplating a career in medicine, Chen joined Medical Makers, an on-campus, DTC-oriented club focused on developing medical devices.

Over the last academic year in partnership with Shirley Ryan AbilityLab, Chen and his Medical Makers teammates have worked on developing a wearable technology capable of alerting nursing staff when incontinent patients need to urinate or defecate. Such a solution could improve patient care and heighten staff efficiency, two wins in the fast-moving healthcare environment.

Embracing the lessons of DTC, Chen researched incontinence, including the physiological signals before or after urination or defecation, connected with practicing biomedical engineers to understand their process, listened to stakeholders’ experiences, and evaluated dozens of potential solutions alongside his team members. During that process, Chen was mindful of not letting design creativity outpace practical considerations.

“It’s been an adventure to find new ideas and consider how they might work,” he said.

Chen and his team are now developing a 3D model of their product — a pad in incontinence underwear composed of a moisture absorbent layer over an anti-microbial layer and connected to a circuit board — for presentation to AbilityLab staff. By the close of this academic year, the team aims to begin testing a working prototype at AbilityLab, collecting feedback and data to inform its subsequent iterations.

“John’s involvement with Medical Makers underscores our hope that DTC students see that design is about solving real-world problems for real people,” Mejia said. “To do that, we need to be empathetic and curious collaborators who are humble with feedback and motivated to improve.”

New perspectives, new interests

On the heels of DTC, Chen said his Medical Makers experience has given him a richer understanding of human-centered design, including the structure and organization necessary to spur accountability and achieve objectives. He’s also inspired by the project’s potential real-world implications.

“We have meetings every Friday, and I leave each week more motivated,” Chen said. “Our research-sharing sessions, brainstorming meetings, and conversations have opened up my mind and made me so much more excited about design.”

So excited, in fact, that Chen is contemplating an engineering career over medicine. He recently applied for internships in bioelectronics and wearables.

“The hands-on, practical nature of engineering work just might be my calling,” Chen said. “It’s work I enjoy and work I feel can have impact.”